Built to Endure the Test of Time

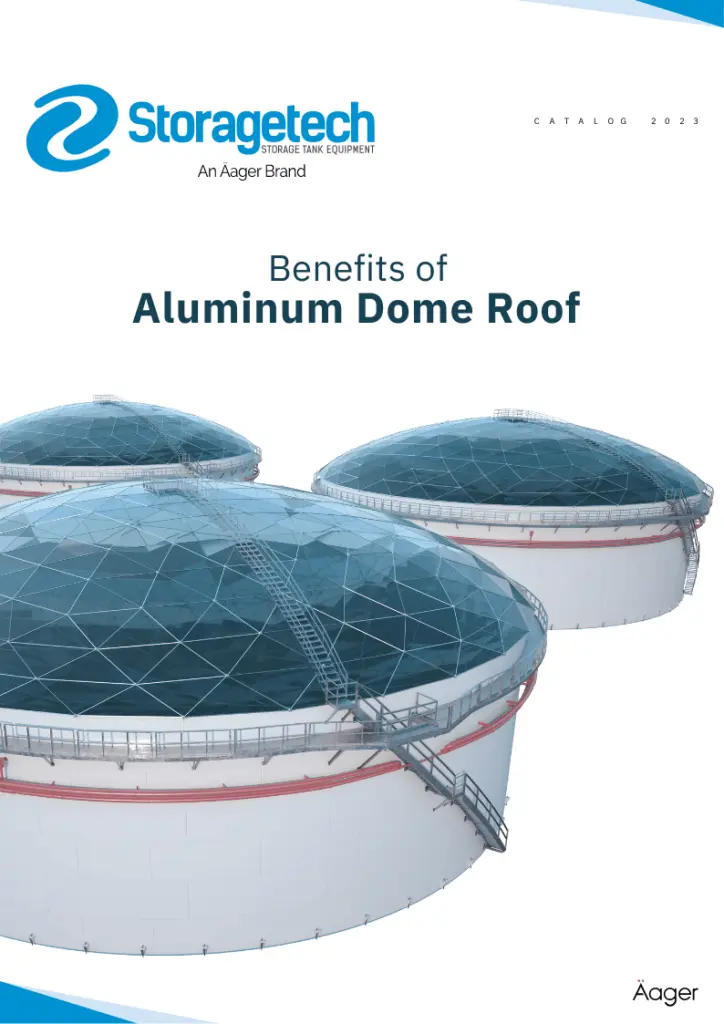

Experience Unmatched Strength and Durability with Dome Roofs

Dome roofs are designed to withstand extreme weather conditions, making them one of the most durable and long-lasting roofing options available. Unlike traditional flat roofs that are prone to leaks and damage from heavy rain and snow, dome roofs are built to withstand heavy loads and resist water, making them an ideal choice for homes and buildings in areas prone to harsh weather.

Unbeatable Strength and Protection

Storagetech’s Dome Roofs with

Advanced Sealing and Gasket Technology

Storagetech’s dome roofs offer superior structural design and sealing capabilities that are unmatched in the industry. Our engineers have designed our domes to provide exceptional strength and durability, making them the perfect choice for a wide variety of applications, from industrial storage to recreational spaces.

Connecting with us is a breeze!

Whether you prefer to call, email, or message us through our website, we make sure that every interaction with us is efficient, effective, and personalized to meet your needs. Connect with us today

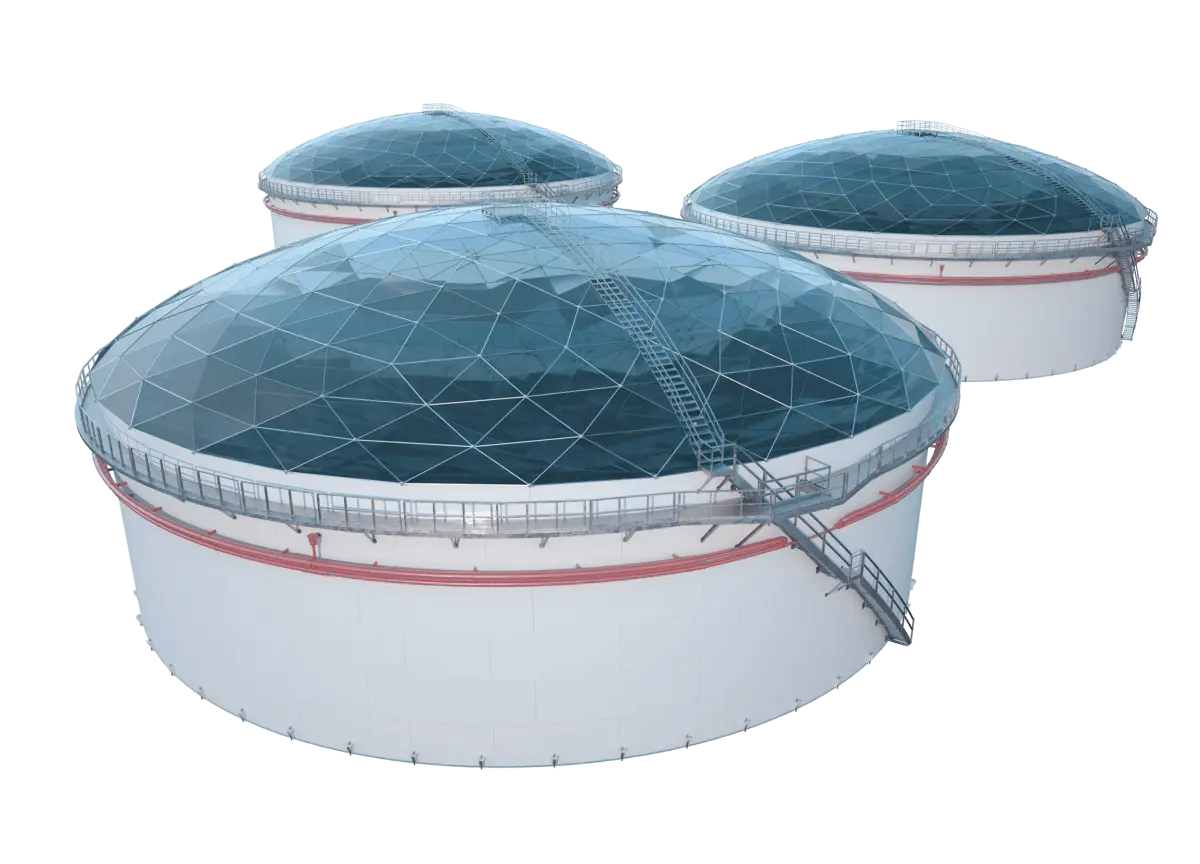

Strength and Durability You Can Count On

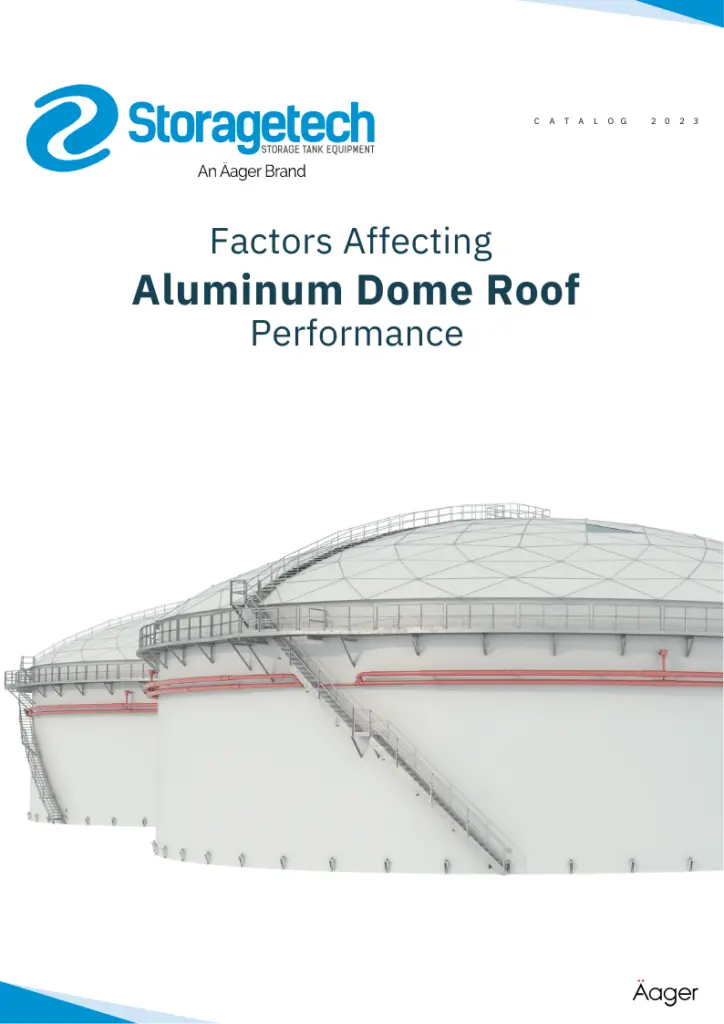

The Structural Design of StorageTech Dome Roofs

At Storagetech, we take pride in our superior structural design for dome roofs. Our team of experienced engineers ensures that every structure is built to withstand even the toughest conditions.

Experience the Future of Roofing with Storagatech's Dome Roofs

Discover the Strength and Versatility of Dome Roofs

Looking for a roofing solution that can provide unmatched strength, durability, and versatility? Look no further than dome roofs from Storagatech!

Strong, Durable, and Versatile

Our Structural Designs for Any Application

Storagetech Engineers ensure that our dome roofs are structurally designed to provide exceptional strength and durability, making them an excellent choice for various applications.

Meeting the Highest Standards

Storagetech Aluminum Dome Roofs Comply with Industry Regulations and Codes

Storagetech Aluminum Dome Roofs are built to meet the highest industry standards and norms, ensuring reliable and long-lasting performance. Our dome roofs comply with API 650 App. G for structurally supported aluminum dome roofs used in oil storage, as well as AWWA D108 for water storage facilities. We also adhere to AWWA D103 for factory-coated bolted steel tanks, AWWA D100 for carbon steel tanks, NFPA 22 for water tanks used in private fire protection, and NFPA 30 for flammable and combustible liquids.

Our dome roofs are designed to withstand various design loads in accordance with ASCE 7 and IS 875, and are built to the aluminum design standards of ADM 2020. Additionally, we comply with EuroCodes, ensuring that our products meet the stringent requirements of the European market. With Storagetech Aluminum Dome Roofs, you can trust that you are getting a storage solution that meets the highest standards of quality and safety.

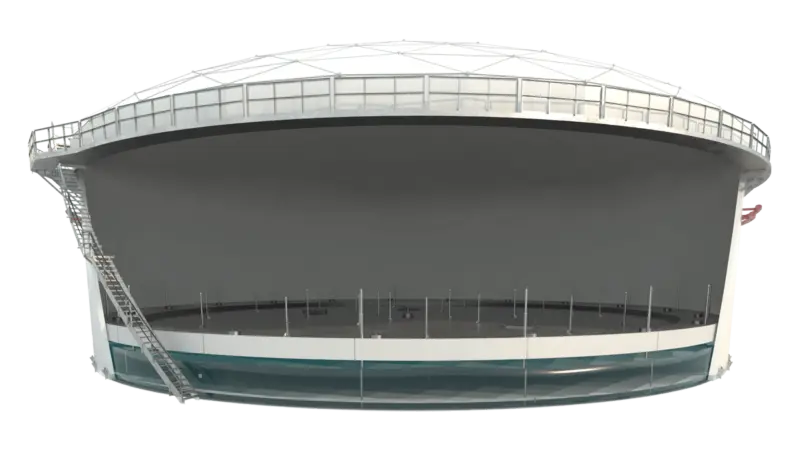

We understand that each storage tank project is unique, which is why we offer customized solutions to meet your specific needs.

Our team of experienced engineers is dedicated to ensuring that our dome roofs are structurally sound, durable, and meet industry standards and norms.

We work with you every step of the way to ensure that your dome roof meets your project requirements.

Our customized design process involves a thorough understanding of your project needs, site-specific conditions, and storage tank contents. This enables us to provide you with a dome roof that is optimized for your specific application.

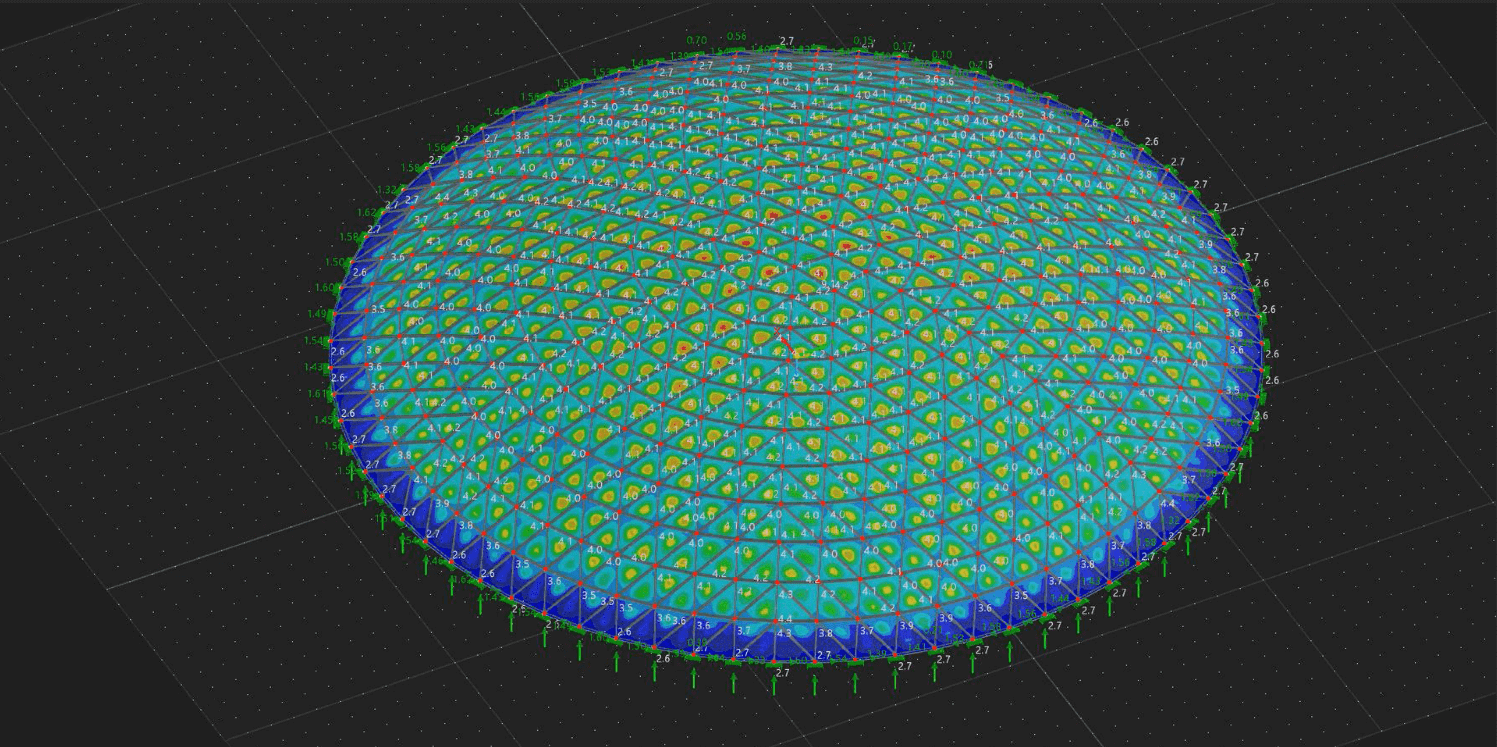

Our engineers use advanced engineering tools and techniques to ensure that your dome roof is designed for optimal performance.

We utilize the latest in 3D modeling software to create a detailed digital representation of your dome roof, enabling us to analyze its structural integrity, wind and seismic load resistance, and other important factors.

Our dome roofs are designed to meet a variety of industry standards and norms, including API 650 App. G, API 2000, AWWA D108, AWWA D103, AWWA D100, NFPA 22, NFPA 30, ASCE 7, ADM 2020, IS 875, and EuroCodes.

This ensures that your dome roof is designed and manufactured to the highest standards, providing you with a safe and reliable storage solution.

At StorageTech, we don't just design and manufacture dome roofs - we also provide expert installation and support services.

Our experienced installation teams are trained to install our dome roofs quickly and efficiently, reducing downtime and ensuring that your project is completed on time and on budget.

We also offer ongoing maintenance and support services to ensure that your dome roof continues to perform at its best for years to come.

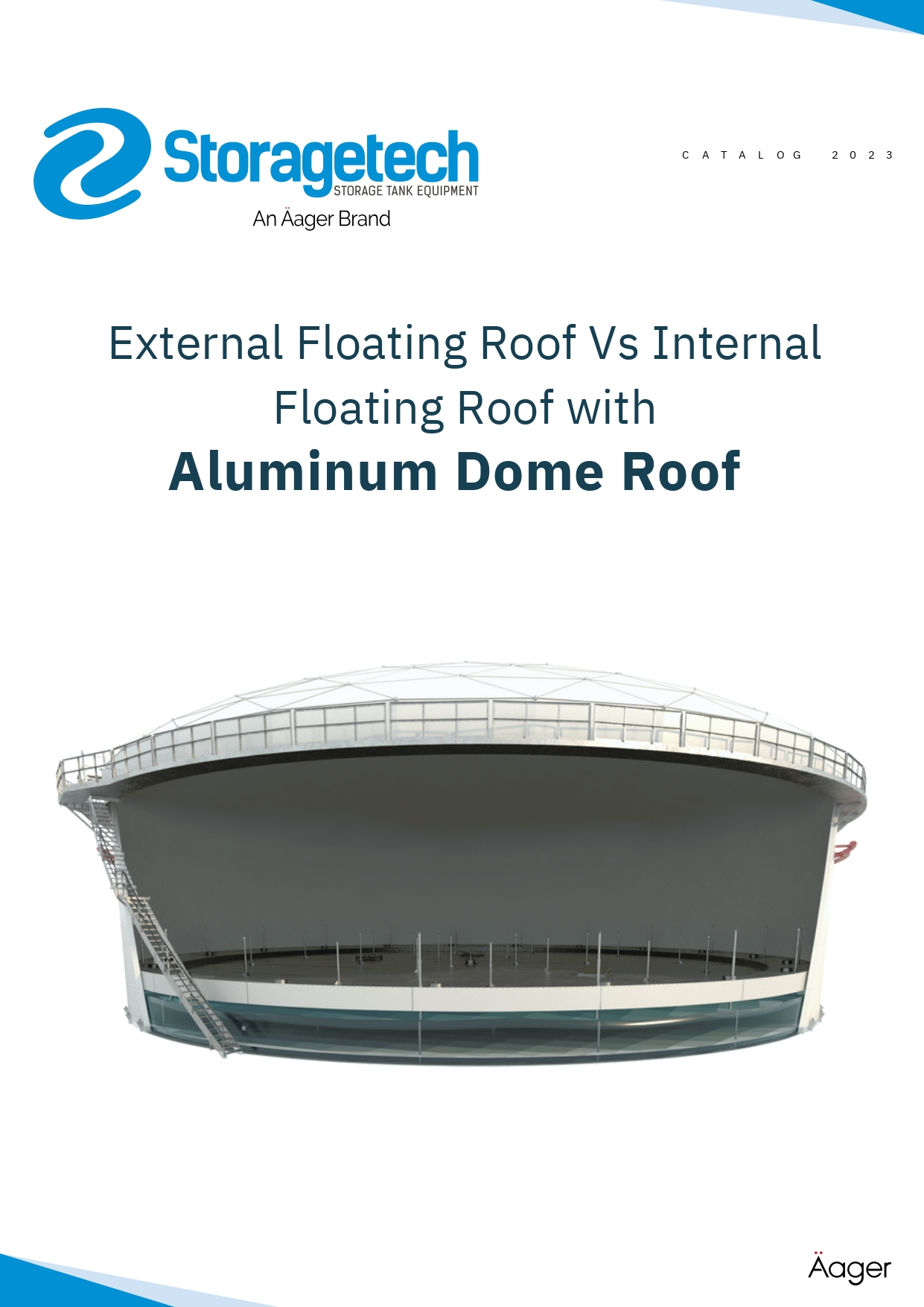

Water & Waste Water

Aluminum dome roofs are an ideal solution for water and wastewater storage applications due to their durability, low maintenance, and cost-effectiveness. These roofs provide a safe, secure, and reliable cover for water tanks, reservoirs, and other storage facilities, protecting against weather elements and potential contamination.

Hydrocarbons

Aluminum dome roofs are also a great choice for storage tanks in the hydrocarbons sector. These tanks are used to store various types of fuels and chemicals, and require a reliable and durable roof to ensure the safety and integrity of the stored materials.

Petrochemical

Aluminum dome roofs offer a number of benefits for the petrochemical industry. They can be designed to meet specific loading requirements, including wind and snow loads, and are resistant to corrosion, making them a reliable and long-lasting option.

Chemical & Special Purposes

Aluminum dome roofs are also a popular choice for chemical and special-purpose applications due to their durability and corrosion resistance. They can withstand harsh chemicals and extreme weather conditions, making them ideal for use in harsh industrial environments.

Why Storagetech Aluminum Dome Roof?

Unmatched Experience in Dome Roof Engineering and Construction

Our team of experts has the knowledge and expertise to create custom dome roofs tailored to your specific needs, whether it's for commercial, industrial, or residential use. You can trust us to provide top-notch service and unparalleled expertise in dome roof construction.